1. Wrap angle

Material

Wrap angle W

Material

Wrap angle W

Crease prevention

for paper

15° - 20°

for Fourdrinier wires

15° - 20°

for FABRIC sieves

20° - 40°

for wet felts

30° - 60°

Material

Wrap angle W

Material

Wrap angle W

Easily stretchable plastic webs, such as polyethylene, polypropylene and similar, according to thickness

1 - 6 µ

60° - 90°

8 - 20 µ

45° - 60°

Greater than 20 µ

45°

Cellophanes

15° - 20°

Material

Wrap angle W

Material

Wrap angle W

Crease prevention and removing creases from textiles

Felts

15° - 20°

Easily stretchable cotton

60° - 90°

Nylon fabric

60°

Coated fabric

60°

Glass-fibre material

60°

All kinds of materials

60° - 90°

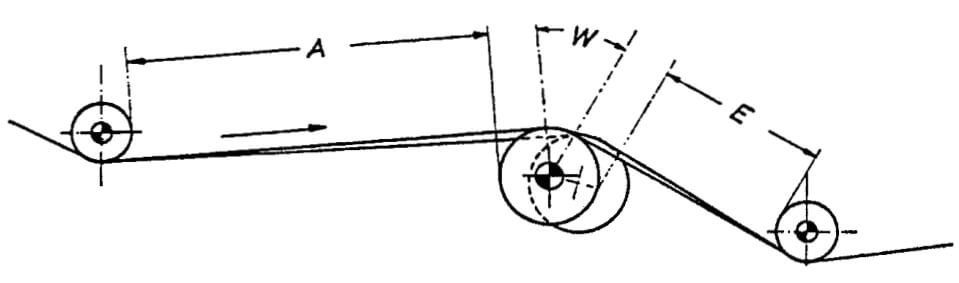

2. Distance to next guide roller

The distance between the spreader roller and the next guide roller should not be too big. Experience tells us the best distance “E” should equal two to three times the diameter of the spreader roller.3. Feed

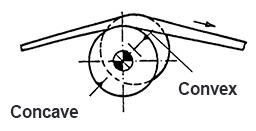

The web should always be fed in from the concave side. The web path “A” can be longer, but it should not be more than 2 x “E”.4. Setting

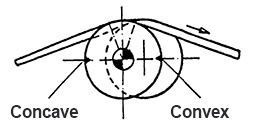

When subject to normal material and tension ratios the spreader roller is set to the position depicted opposite. That ensures loads are applied uniformly to the whole of the roller, which prevents the rubber covering wearing unevenly.

When subject to normal material and tension ratios the spreader roller is set to the position depicted opposite. That ensures loads are applied uniformly to the whole of the roller, which prevents the rubber covering wearing unevenly. When processing webs with slack edges the concave side of the roller is swung out from its normal position until the edges bear firmly on both ends of the roller.

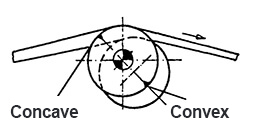

When processing webs with slack edges the concave side of the roller is swung out from its normal position until the edges bear firmly on both ends of the roller. When the middle of the web is slack the convex side of the roller is swung out from its normal position until the middle of the web is tensioned properly.

When the middle of the web is slack the convex side of the roller is swung out from its normal position until the middle of the web is tensioned properly.